Yaren Makina Pasteurization Tunnel Solutions;

Yaren Makina Fruit Juice Pasteurization Tunnels

Yaren Makina offers highly efficient and fully hygienic solutions designed for the fruit juice and beverage industry, positioned at the heart of production lines with its pasteurization tunnels. Pasteurization tunnels are not just machines that heat treat bottled products; they are also a strategic investment that represents a company’s food safety culture, commitment to efficiency, and brand reputation. This document examines the operating principle, engineering infrastructure, and the advantages Yaren Makina pasteurization tunnels offer to factories from a technical perspective.

- The Role of the Pasteurization Tunnel and Process Logic

Fruit juice, lemonade, nectar, and similar beverages are highly susceptible to microbial growth due to their natural sugar, organic acids, and dissolved oxygen content. When the product is pasteurized only before filling, the risk of post-filling contamination remains constant. Yaren Makina’s pasteurization tunnels come into play precisely at this point. Once the product is packaged, it is subjected to a controlled thermal profile, reaching its final safety level.

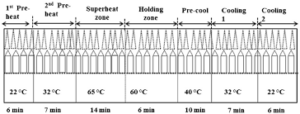

The process involves bottles traveling on a conveyor belt through a tunnel divided into zones. Preheating occurs in the first zones, main pasteurization in the middle, and gradual cooling in the final zone. This ensures that the product reaches the specified pasteurization unit (PU) value, inactivating target microorganisms. Controlled management of the PU value is critical for shelf life, product stability, and preserving the flavor profile.

Yaren Makina develops individual process recipes for each product group. Higher PU values are used for high-pH beverages and lower PU values for acidic products. This avoids unnecessary heat load, reduces energy consumption, and prevents flavor deterioration.

-

Technical Infrastructure and Process Diagrams

- Technical Specifications – Yaren Makina Pasteurization Tunnel

The table below summarizes the technical specifications for a typical Yaren Makina fruit juice pasteurization tunnel. Capacity, dimensions, and equipment options can be customized on a project-by-project basis to meet customer needs.

Parameters Value / Range

Capacity 3,000 – 40,000 bottles/hour

Suitable packaging types Glass bottles, PET bottles, metal cans

Operating temperature range 22 – 95 °C

Target PU range 8 – 120 PU

Material 316L stainless steel body, food-grade seals

Number of zones 5 – 12 zones (preheating, pasteurization, cooling)

Conveyor belt width 900 – 2,500 mm

Power source Steam, hot water, or thermal oil

Control system PLC + touchscreen HMI, remote access option

CIP compatibility Compatible with integrated or external CIP systems

Standard protection classIP65 control panel, IP55 motors

Safety equipment Emergency stop buttons, safety door switches

- Thermal Design and Zone Architecture

Yaren Makina tunnels offer a long-lasting and maintenance-friendly structure with their 316L stainless steel bodies and optimized zone architecture. The thermal design is based on three fundamental objectives: uniform heat distribution, minimal thermal shock, and maximum energy recovery.

Preheating zones are zones where packaged product is gradually transferred from ambient temperature to process temperature. This eliminates the risk of cracking in glass bottles, deformation in PET packaging, and distortion in metal cans. In the main pasteurization zone, water temperature and spray flow are controlled, maintaining the product at the target temperature for the desired duration. A stepwise approach is adopted in the cooling zones, reducing the product to the target storage temperature without exposing it to sudden cooling shocks.

The spray nozzles used within the tunnel are selected to ensure high efficiency and uniform distribution. Nozzle placement, conveyor width, and bottle stacking are all considered together. This ensures that each product unit is exposed to the same thermal profile, minimizing variations within the batch.

- Automation, Traceability, and Digitalization

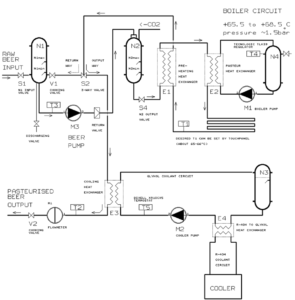

Yaren Makina’s pasteurization tunnels are managed by a fully automated PLC-based control system. Operators can monitor all zone temperatures, belt speed, PU values, water tank levels, pump statuses, and alarm logs in real time via the touchscreen HMI panel. Predefined recipes for different products can be activated with a single touch, minimizing line downtime during product changeovers.

The system reads data from temperature sensors and temperature probes with high resolution and controls it with a PID algorithm. PU calculation is performed online; when the desired target is reached, the system automatically optimizes the belt speed or zone temperature. This digital control structure ensures both energy consumption and process safety.

Thanks to the data recording and reporting infrastructure, temperature, PU, and alarm history for each production batch can be stored. This fully meets the traceability requirements required by food safety standards. Yaren Makina also offers interface solutions for businesses that can integrate this data into ERP or MES systems.

- Hygiene Design and CIP Integration

In the food industry, hygiene is achieved at the design stage. Yaren Makina tunnels are manufactured according to hygienic design principles, featuring a piping design that eliminates dead spots, a sloped base structure for rapid drainage, rounded corners, and easy-to-clean surfaces. All seals are made from certified materials suitable for food contact.

CIP (Clean-in-Place) system integration is a standard part of Yaren Makina solutions. The tunnel can be automatically washed with external or integrated CIP units; detergent, hot water, and rinsing phases are prescribed via the PLC. Proper CIP management ensures a low microbial load, prevents biofilm formation, and eliminates the risk of cross-contamination between products.

- Energy Efficiency and Sustainability

Today, energy costs play a significant role in the operating expenses of food production facilities. Yaren Makina prioritizes energy efficiency in its tunnel pasteurizer designs. Heat exchangers enable energy recovery between hot and cold water, minimizing the need for fresh steam or hot water. Water transfer between zones is managed with smart valves, preventing unnecessary recirculation.

High-efficiency motors and frequency inverters are used in pump and fan motors. This ensures that the tunnel consumes only the required capacity. Businesses achieve significant reductions in their energy bills in the long term while also reducing their carbon footprint. This approach contributes to both sustainability goals and facilitates successful supplier audits by international retail chains.

- Catalog-Format Hardware and Options

Standard Equipment

- 316L stainless steel body and support legs

- High-efficiency stainless steel conveyor belt

- Zone-based water spray collectors and spray nozzles

- PLC-controlled automation system and touchscreen operator panel

- Temperature sensors, level switches, and flow control elements

- Heat exchangers for energy recovery

- CIP connection points and drain lines

- Safety doors, locking mechanisms, and emergency stop buttons

Optional Equipment

- Fully automatic CIP unit and chemical dosing system

- Recipe-based automatic PU control algorithm

- In-line data recording, reporting, and remote monitoring package

- Special conveyor belt layouts (mixed packaging or multi-lane applications)

- Energy consumption monitoring module and performance reporting software

- Stainless steel control panel and increased IP protection rating

- Special roof hatch designs and fully opening maintenance doors

- Application Areas and Integration

Yaren Makina’s pasteurization tunnels can be used in fruit juice and nectar production lines, as well as for iced tea, still beverages, malt beverages, sauces, and similar products. Thanks to their design compatible with glass, PET, and can lines, businesses with diverse product portfolios can manage all product groups from a single platform.

Integration with the filling machine, labeling line, packaging unit, and palletizing system is considered within the scope of project engineering. Conveyor transition points are optimized according to product flow and factory layout. Yaren Makina’s engineering team supports the customer during the project phase with layout drawings, process flow diagrams, and capacity scenarios.

- Yaren Makina’s Engineering Approach

Yaren Makina positions itself not only as a machine manufacturer but also as a process consultant in pasteurization tunnel projects. In the first phase, the product portfolio, target shelf life, existing factory infrastructure, and growth plans are analyzed. Then, capacity scenarios and return on investment are evaluated together. This approach ensures the customer has an investment prepared not only for today’s needs but also for future capacity increases.

FAT (Factory Acceptance Test) and, when necessary, SAT (Site Acceptance Test) procedures are implemented for each project. During the commissioning process, operator training, technical briefing for maintenance teams, and the optimization of process recipes are part of Yaren Makina’s standards. Spare parts and service support are designed to cover the entire lifecycle of the machine.

döngüsünü kapsayacak şekilde kurgulanır.

- Conclusion – Reliability, Efficiency, and Added Value to the Brand

Fruit juice pasteurization tunnels are critical equipment in the food industry, directly impacting product safety, shelf life, and quality consistency. Yaren Makina combines this equipment with high engineering standards, hygienic design principles, and a digital control infrastructure to offer businesses a comprehensive solution. Energy efficiency, low maintenance, and flexible capacity management shorten the return on investment, positioning the brand more reliably and strongly in the market.

In conclusion, Yaren Makina pasteurization tunnels provide a scalable and sustainable infrastructure not only for today’s production facilities but also for the future. For businesses that prioritize food safety, process excellence, and corporate reputation, these tunnels are an essential component of the production line.

The primary source of cooling used is water circulated in each zone of the Cooling Tunnel. New water is added to the system only when the reservoir water exceeds the preset temperature. Evaporative cooling is provided by exhaust fans to cool the circulating water and product.

Yaren Makine Cooling Tunnel is built using modular components that provide ease of transportation and installation, ease of adding or removing lengths for future production requirements, and dividing the cooler into separate zones. The various zones can be designed to cool only or to keep the product at elevated temperature for a certain period of time to provide pasteurization prior to cooling. A medium temperature water zone can be applied to the feed end to prevent thermal shock and cracking in glass containers.

PROPOSAL FORM